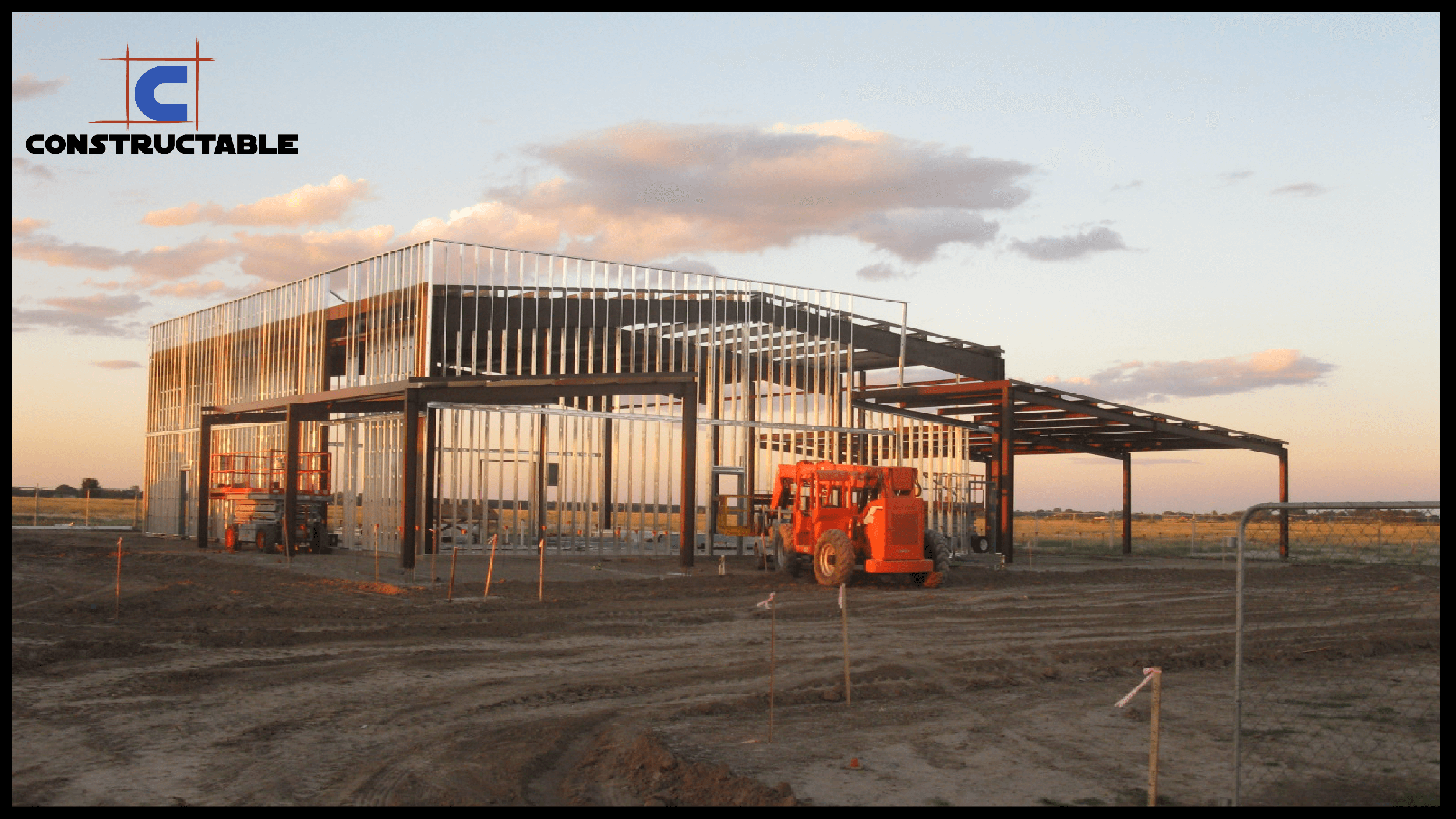

Why a Metal Building is Right for You

From small, single room control centers to large distribution centers and warehouses, metal buildings are the structure of choice for much of the industrial construction world. A quick glance at any industrial complex reveals an operations and maintenance building at the center of it, often with beefed-up specifications for the various needs of that plant. Visit any oil field, remote location, small town and you will see most structures built as being pre-engineered metal buildings.

Metal buildings are gabled structures spanning more than 100 feet in a very flexible and versatile way. Not only do these buildings offer myriad choices for design, they do it in a quick and cost-effective way. While once maligned, the metal building has undergone a revolution both in quality and in popularity. This trend toward such buildings is because of four reasons:

- Versatility

- Durability

- Economy

- Velocity

With such an effective and efficient method of building at hand, metal buildings are right for you and for your project.

Alexander Newman’s Metal Building System Design and Specifications touts the statistical dominance of the metal building in the low-rise building arena. Such buildings “comprised 65% of all new one- and two-story buildings with areas of up to 150,000 sqft in 1995.” This means an industry totaling $2.21 billion in sales with 355 million sqft installed that year alone.

The metal building is here to stay.

What are metal buildings?

Traditional building styles included wood structures, bricks, concrete, and various other methods. However, once steel fabrication became more advanced and so inexpensive, metal buildings muscled their way onto the scene. Now, both large and small steel fabricators have found faster and better ways of creating such materials for assembly by creating whole kits of actual buildings called “pre-engineered metal buildings.” These buildings are sections of steel designed and fabricated before they ever hit the project site. It is these kinds of buildings that have taken over the industrial low-rise building market. Below are the four main reasons for such a revolution:

Versatility

Metal buildings are versatile structures that are relatively easy to design, build, and complete. Dream a little about the specifications of your project; bump out this wall; move this room; add in this feature. Metal buildings can accommodate it.

Commonly a large rectangle floor plan, this is the simplest a metal building can be. Project owners can find a multitude of applications for such buildings including garages, shops, staff offices and staff housing, repair centers, hangars, and many more types of structure.

While very useable and versatile, indeed, metal buildings can be much more than simple rectangle floor plans. They can include very large warehouses, multi-story structures, and blast-resistant buildings. And versatility is one of the most important points of having such buildings on your project. There is not an industry today that could not find some application for such a structure.

Durability

Industry nearly always calls for durability; and the hardened steel of such metal buildings is equal to the task. Durability in metal buildings means blast resistance, sound mediation, and temperature control in extreme environments. Look at any refinery, chemical plant, factory, water treatment plant, or even large warehouses and you’ll likely find a metal building among the construction.

Why is it that they have become so universal? They serve a very important role in industry of being so versatile (as mentioned above) that they can become life-saving structures in the eventuality of industrial incidents and accidents.

In blast resistance the key measurement is the atmospheric pressure. On one end of the spectrum, as in outer space, too little atmospheric pressure on a human can kill him or her; too much atmospheric pressure is just as deadly for opposite reasons. While metal structures have not become so ubiquitous as to be cost-effective in outer space, the too-much pressure problem is one that can be solved on earth. And that is exactly why operations and maintenance buildings can be made more durable to protect the staff within. Consider an example from an oil or gas plant. Unfortunately, accidents and incidents do happen, but if a metal building housing your staff is equipped with proper blast remediation structural techniques, the people inside of it can remain safe; the building itself takes the brunt of the blast, leaving the staff unaffected internally. Constructing more durable walls, windows, foundations, and structural supports is both essential and very doable in construction. Constructable has certification through the Baker Risk organization for this very reason.

Consider other needs for durability, like heat or cold. Many industrial structures are built in remote places and in environments with varying extremes of weather or temperature. The scorching oil and gas fields of the Southwest are rivaled by the extreme wind speed of wind farms in the Midwest. Every industrial complex in such harsh places needs a durable building meant to withstand the elements in service of our most important resource: human resources.

Velocity

The third reason for such a meteoric rise for metal buildings is that they are very quick to construct. There are three reasons for this:

- Linear construction: Pre-engineered metal buildings benefit from a straightforward method of construction with very little need for phasing. One simply clears the land, prepares underground work and utilities, readies the pad, pours the slab, sets the anchor bolts, and it is now time for the pre-engineered metal to be quickly assembled. Instead of a months-long process, these buildings, at the erection phase, can be erected in weeks to even days.

- User manual included: Yes, every building has a user manual called “blueprints,” but pre-engineered metal buildings go beyond that and have a factory-provided separate set of instructions detailing all the steps necessary for erection. Much like a grown-up LEGO set, these instructions make it very easy to understand visually what needs to be done, making the task much quicker.

- Manageable parts: Pre-engineered metal buildings are intended to be manufactured offsite, shipped on flatbed trucks, and assembled with small cranes or lifts. For that reason, the objections of having to procure massive construction machinery, coordinate the impossible undertaking of oversized load transportation, and assemble a small army of manpower to construct the largest of buildings and structures do not apply. A good erection crew can do nearly all the work with a lift or small crane and with fewer team members than traditional building types.

In the construction world time truly equals money: hourly wages, equipment rental fees, toilet rentals, office trailer rentals, and many other general conditions are the most visible reason for a long schedule incurring more cost. But there are unseen things like opportunity cost and liquidated damages that are lost (opportunity cost) or assessed (liquidated damages) when a schedule lengthens beyond contractual agreements. If one wants a quick building erected to avoid such distasteful fines, then the pre-engineered metal building is the way to do it.

Economy

For years pre-engineered metal buildings have dominated the market simply because they were the most inexpensive. Not to mention the velocity at which they are built, the durability of the structure, and the versatility of their design, pre-engineered metal buildings are just plain inexpensive. In fact, one objection raised to their use was quality. These structures were so inexpensive to build that they gained a reputation for being poor building solutions. You get what you pay for in most of areas of reality. But in decades of building sophistication, strict code regulations leveled at such structures, and the competitive market for suppliers, pre-engineered metal buildings have now grown to become a quality solution.

A second objection to steel structures is in the form of price: while once extremely affordable, their price is on the rise. It is true that the price of steel has sharply increased to all time highs in recent years (see our research on reasons for this occurrence and our predictions on steel prices in a previous blog article HERE), pre-engineered metal buildings are still competitive solutions in the low-rise industrial building market. This is a testimony to the growth in the efficiency of design and fabrication and the skill of the building method over the years. In our thinking the price of steel cannot continue to climb forever for various reasons.

While no material is cheap, pre-engineered steel still represents a very economical solution for most low-rise industrial buildings. In fact, without steel most of our modern structures would not be possible. It is because of steel’s strength in proportion to its weight that we have modern skyscrapers. In the same way, consider pre-engineered metal buildings a low-rise version of such structures.

The last objection to a pre-engineered metal building is that their universal use and high demand has yielded long lead times for procurement and delivery. A difficult hurdle to overcome, yes, but this is not so much an objection to their use but actually an endorsement: the fierce competition to getting such a building shows just how much people should use them. And while lead times can be very large, Constructable knows how to use multiple resources and signed agreements with suppliers to procure successfully and still with good quality.

Why a metal building is right for you

Simply, with such an effective and efficient method of construction at hand, metal buildings are a fantastic solution for your project. They are versatile, durable, quick-to-construct, and economical.

Constructable’s preferred method of building construction is in managing and constructing pre-engineered metal building projects in their entirety, from dirt work to final punch lists and everything in between. We source from multiple national and local vendors to get the best lead times and prices for our clients while still maintaining quality. Our years of experience in procuring, engineering, and constructing pre-engineered metal buildings make us the ideal solution for your industrial projects. Let us guide you through the construction process as we build your ideas into reality. We created a metal building guide to help you through your construction project. Download your metal buildings guide below and let us work together on your project.

Source: Metal Building System Design and Specifications, Alexander Newman

To Download