Design/Build: Procurement

Purchasing the correct materials, equipment, suppliers, and subcontractors is essential to a project’s success. The quality, lead time, and quantities available all figure as factors of the equation. Projects are improved in both schedule and price by using the design/build method for construction. That is because the design/build method allows the contractor to begin the procurement process immediately, as soon as an agreement is reached.

Design/Build: An integrated method

The design/build process includes four steps, design and engineering, procurement, construction, and management. Because the contractor is involved with the project in the design and engineering phases, procurement for such a project has great advantages. Among them, design and engineering commonly take painstakingly long to complete. However, if the contractor can start the procurement process while design takes its painstaking course. One does not need to know the final dimensions of the bathroom stalls or the color of the custom industrial kitchen’s wall to be able to know large quantity items like concrete, dirt, and even metal building elements can be purchased well in advance.

This is because the majority of materials, equipment, suppliers, and subcontractors can be engaged before drawings are 100% complete. It is obvious that expensive and large-implication items like dirt, concrete, structural steel, and various other materials can sidetrack a project if they are delayed in shipping or delivery. How better to mitigate this than by purchasing immediately, when the majority of project needs are already known?

Crisis averted: The price of steel and shipping delays

How does one procure materials subject to worldwide trends in pricing that need to be designed and engineered before even ordering? For example, a pre-engineered metal building must have exact specifications and design before being ordered. (For more in depth research, see our article on the price of steel and global volatility HERE.) These kinds of structures currently have very long lead times. So how does a project not get set back by such long lead times?

Again, the answer is the design/build method. Procurement in this method of construction is the most salient and important way to save money and time. Yes, high-specification materials like pre-engineered metal buildings need to be ordered at a further point in the design progress, but you can still jump into production line more quickly than if you waited until 100% and did a traditional design bid build process. We are talking about months of reduced schedule because the final portions of the drawings are always the trifling issues that arise and take the longest. These trifling issues do not have to slow down the major portions of your project procurement. For example: commonly the metal superstructure has already been long completed once you must argue about and mind the changes in the electrical circuits being correct.

The crisis of long lead times is averted with the design/build method.

Time is money: How design/build saves both

Procurement is, by definition, the most expensive part of a project. This is when you spend money to get your project off the ground. The important question here is: do you want to do the picking and choosing on your own, or would you like a seasoned professional with years of experience to help find the best deals, shortest lead times, and best suppliers and subcontractors?

In a successful procurement cycle, you are not only saving money, but also time. Though budget is often the most important part of a project, the schedule can easily intrude on our carefully-planned and executed finances. Why is that? A delay or supply chain breakage will charge a great deal against the budget. What costs more than employing subcontractors and help to sit around on site while your materials are struggling to be delivered? Does anyone enjoy paying for the various rental equipment to sit around in disuse? The liquidated damages threatening at the end of a project will cut into a budget faster than anything.

The hidden cost of poor procurement: Opportunity cost

Opportunity cost is the advantage that your project brings to your organization or bottom line. If your company moves fastest to bring a certain good or service to the market, perhaps the speed and extra cost it takes to move so quickly is worth it? Can you muscle out your competition by being the first to market? Is your project, once completed, solving an issue that is bringing daily grief and problems in your organization? Can you capitalize on a quick project to make your organization more efficient and capable in the market? That is opportunity cost slipping away if you cannot get a completed project on the ground through good procurement.

Procurement can set you up for a faster project and quicker time to keep that opportunity cost from slipping away. One of our previous blogs speaks about the savings that such a process can yield for you in terms of opportunity cost. We reproduce a modified example here:

Project duration with traditional procurement: 100 days

Project duration using design/build procurement: 80 days

Cost per day to be made with your project commissioned: $5,000 / day

Opportunity cost of commissioning your project 20 days early: $100,000.

Cost to speed up your project by 20 days: $20,000

Total opportunity cost on the project (opportunity cost – cost to speed up your project): $80,000

Often when we look at price alone we miss out on the opportunity cost. The design/build method is a key to getting the most value out of your building when time is of the essence.

Constructable knows how to do procurement through the design/build process. We focus on the fastest delivery and best price possible while factoring in the opportunity cost for our clients. See some of our design/build projects below to learn more about our successes with this method of construction.

Design/Build Projects

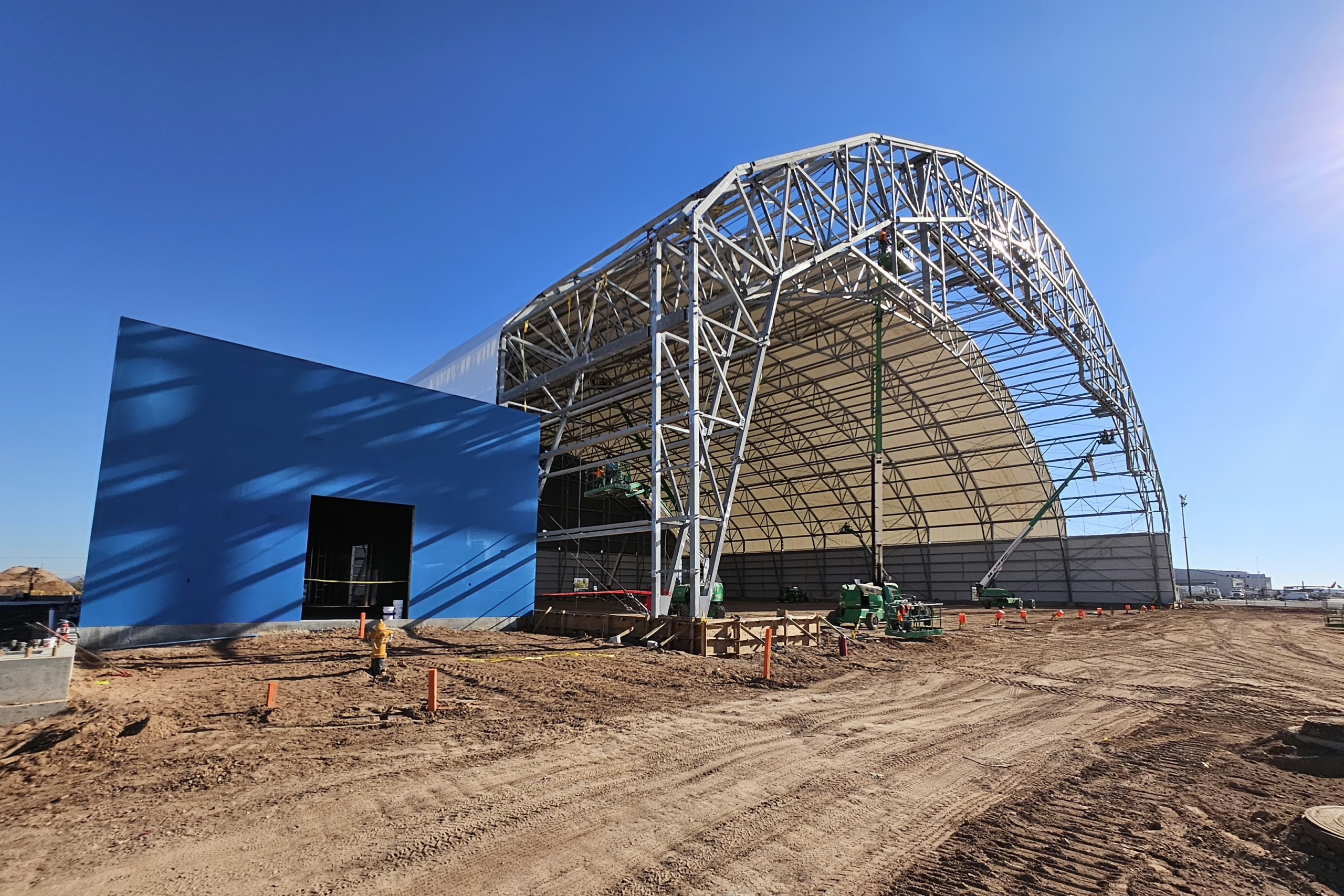

Aviation Structures Design Build Industrial Structures

Aircraft MRO Hangars

New MRO operations build of two new 90,000 sq. ft. of wide-body aircraft hangars, 60,000 sq. ft. of storage and shop support, the only 777-300ER passenger freight modification center in the Americas

Design Build Energy Structures Industrial Structures Renewable Energy Structures

Wind Farm O&Ms

O&Ms: a specialty for wind farms.

Energy Structures Industrial Structures Oil and Gas

Cryo Compressor Building Addition

Large scale cryo compressor building addition to an industrial gas plant in West Texas.

Children and Youth Centers Design Build Non-Profits Renovations Worship Centers

The 180 Building

Remodeling an entire building for improved optics and functionality.

Children and Youth Centers Design Build Non-Profits Worship Centers

Kids On The Move Building

The most unique, challenging, and rewarding project of our history, we took over a failed job site to bring it to an award-winning success as our favorite project.

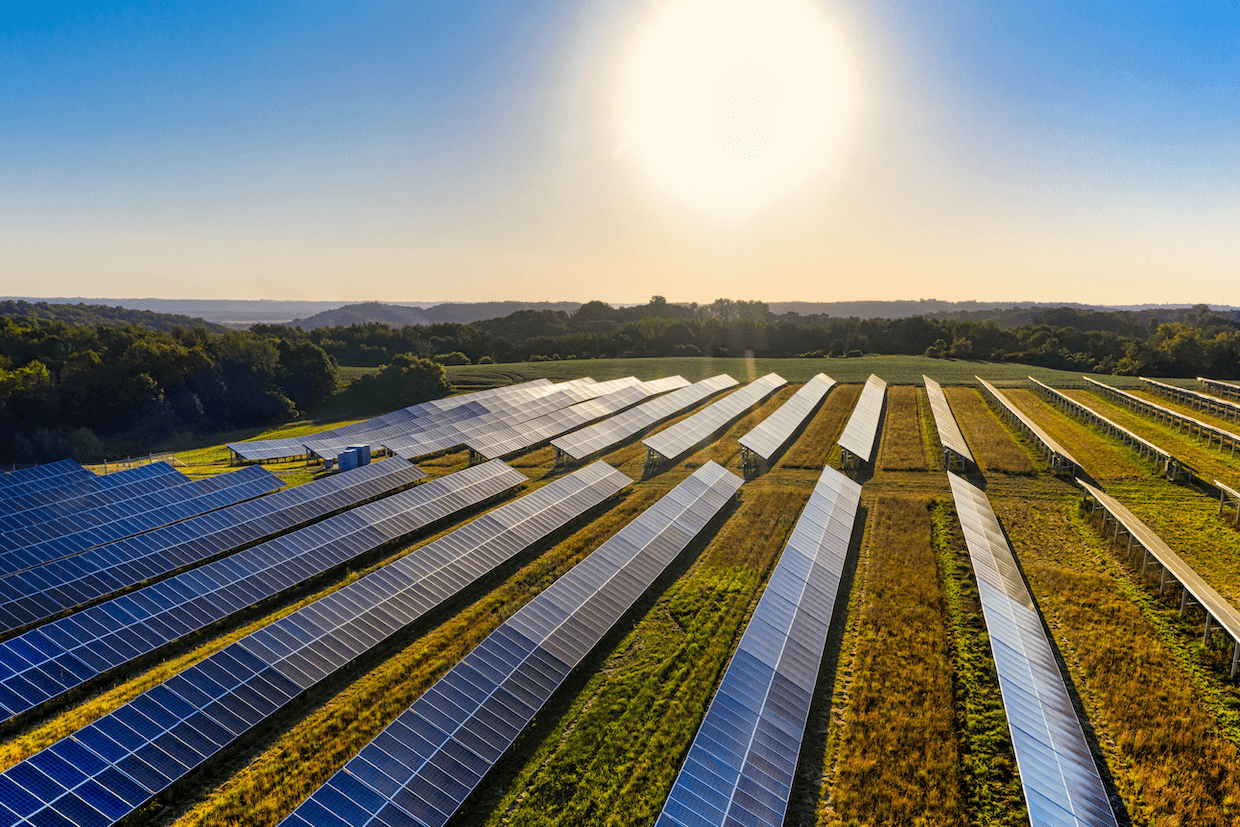

Design Build Energy Structures Industrial Structures Renewable Energy Structures

Solar Farm O&Ms

O&Ms: a specialty for solar farms.